I’m sharing the step by step tutorial to build your own built in shelving around a cased opening… even with a drop ceiling. This modern DIY built in shelving is easy to make by yourself with these tips.

As we’re building my office out of an unfinished basement space, there are so many projects I’ve wanted completed in here and very limited time that Shane and I can work in there together. Which could be a downer and mean less projects, but I’m not afraid of a little trial and error on my own and am feeling so empowered taking on big DIYs like this solo.

I’ve been designing our builds since we started renovating our last house 5 years ago, but usually Shane and I would build as a team. Since I know how I want it built… and I know how to use the power tools, it was about time I took ownership and started doing some of the building myself! I started small this summer and built this toy chest for my kids. Then it got a bit bigger (although used some hacks!) and built this rolling craft table for my office. Now, these built in shelves around the cased opening!

I’m SO happy with how they turned out. Building built in shelving with a drop ceiling was a bit of a design challenge as we’d only built them in the past by using the ceiling as a support. This time around I used the side and back walls as my anchor points and had everything built from the ground up.

Ready to see the DIY tutorial and how I was able to make them by myself? Big thank you to The Home Depot Canada for believing in my vision for this space and partnering to see it come to life!

Before I get to the nitty gritty- if you’d rather wrap your head around this in video form- I saved an Instagram story with all my progress and thought processes on this diy built in shelving project. You can check that out right here.

You’re also going to realize pretty quickly that I’m not a professional carpenter… I’m guessing if you landed here- you aren’t either. I hope that the non-technical language and accessible design helps you feel a little more confident taking on a project in your own home! As always- take on any projects at your own risk ;)

How to Design Built in Shelving

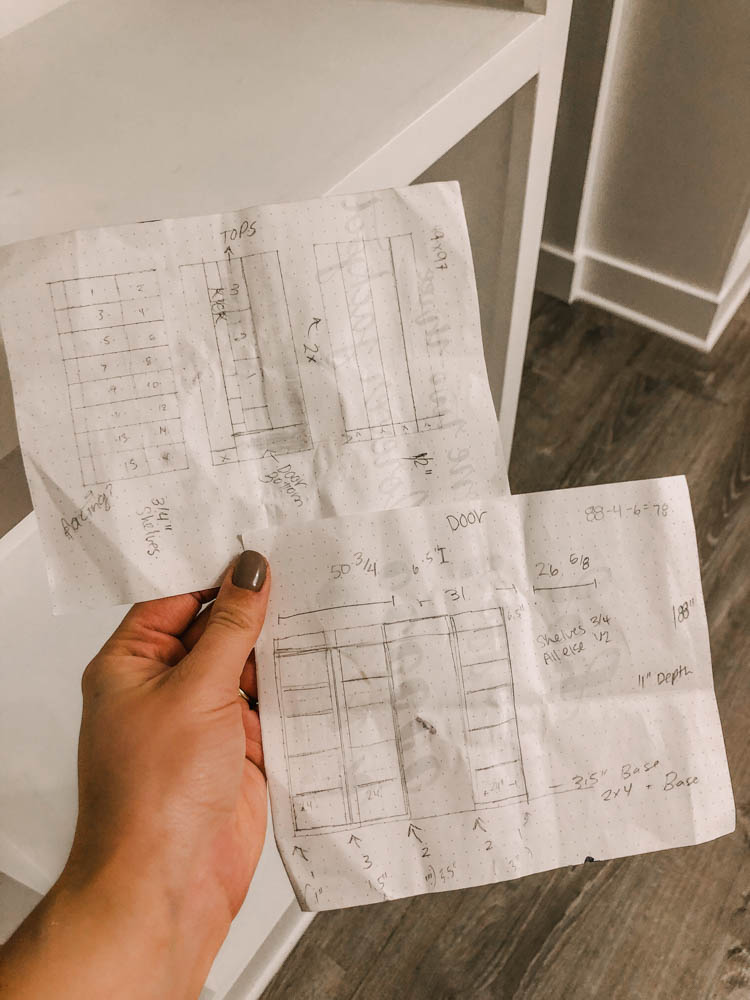

The first thing you’ll need to do is design your shelving for your space. Here’s how I did that. I always use graph paper or dot paper to draw it out while I’m deciding these design measurements. I also estimate everything when I’m designing, then get really specific when I’m building. That’s just how my brain works- but Shane would prefer to be specific in these steps too- so if your brain works that way. Ignore my ‘ish’ measurements here and sub your very super specific ones, k?

Measure out your space and decide how many shelves you want to break it into width wise. For me, I had just over four feet on one side of the door and about two feet on the other side. This broke well into 2 foot (ish) sections.

Then, you can decide how many shelves you’d like high. I wanted to have a good size header as we are hoping to mount a barn door to the top of this. If you were wanting to add a library ladder or something similar, you’d want to account for this as well. I also wanted to have a standard baseboard wrapped around the base. After deciding to leave about 6″ for the header and 4″ for the baseboard, I decided I’d like 5 cubbies.

The last thing you’ll want to decide is how deep you’d like your shelves. Since we have that access panel to the right of the built ins we needed to keep these to 11″ deep. For the sake of purchasing material I used these rough measurements.

How to Calculate Materials Needed to Make Your Own Built In Shelving

Given how I’d designed the shelves, I used the rough measurements to make a materials list. So each shelf needed 2 feet long of 11″ wide material and I needed 6 of them. (take into account that top ‘shelf’ that you case in for the header) I chose to use 3/4″ MDF for these. Uprights, I needed 5 to build the frame of the shelves (11″ wide by 77″ long). I also needed an additional 6 uprights- which is how I supported the shelves, I’ll share more about that later. I used 1/2″ MDF for this.

I also needed to cover the header and baseboard- so you’d add those measurements in for 1/2″ MDF. To calculate how much MDF or plywood you need for a project, I like to draw it out again. I’m super visual so I find drawing it out lets me figure out the best use of materials so I have less waste and so I can take advantage of Home Depot’s cutting services. I draw out a 4×8 sheet and then section it off. For me that meant having all the MDF cut into 11″ strips at Home Depot. This is the only way I could build built in shelving myself. I can’t handle 4×8 sheets of MDF through the tablesaw at home… by myself. The 11″ strips? Easy, friend.

The other materials you would need to calculate are trim (I faced the entire front with 1×2 MDF trim) and 2x4s for your base and header. The trim should be fairly easy to calculate if you have your design drawn out. Just measure how many feet you need for the uprights, and then for the shelves. This trim just bulks the shelves up to make them look less like a particle board bookshelf (I know you know the ones) and more like custom built in cabinetry.

The 2x4s are the hidden construction. I built a base for each section of shelving and a matching header for each section of shelving. You’ll essentially need 2x the width of your shelf and 2x the depth of your shelf for each the bottom and top (so for me that amounted to (2ftx2 + 11″x2) approximately 6 ft of 2×4 for each base and each header.

How to Build Built in Shelving Yourself

I started at my outside walls and put the first uprights in place I used screws into the studs, so make sure your screws are 2 1/2″ or even 3″. You don’t need to worry about how the screws look since you will be covering this piece almost entirely. After your wall panels are done, time to build the base and headers!

Here you’ll need to get specific on your measurements. Make sure to take off the width of the MDF uprights that run to the floor when you’re dividing how wide you need each shelf to be.

I built these wood frames/bases out of 2×4 and attached them through the MDF upright into the studs on the side walls and on the back wall. I did this for both the base and the header. This is where your structure will come from- it’s what holds it all to the wall so make sure to hit the studs!

Since I was doing this solo, I found it easiest to start drilling my screws in at pre-measured points (where the studs are) before lifting the header to place and levelling it. I used a 2ft level for this. Make sure to level the base too- if your floor is not level (mine weren’t since we laid flooring over concrete!) use shims to level it up before securing to the studs. Everything will be built off of this so take your time to make it right.

Work from the wall towards the cased opening- or if you’re going wall to wall, you’ll want to work from each side simultaneously so if your measurements are a hair off- you take that in your middle shelf instead of the side ones- keeping it symmetrical. So after you put the wall panel upright in, then the base and header, add another upright to separate your shelving sections, screwing it to the header and the base, then add another base and header. Screw this one through the MDF panel into the other header and base and into the studs in the back wall. Finish it off with another edge panel/upright. You’ll be trimming this out so all screws will be hidden.

Once you have your uprights, base and header in… it’s time to watch this diy built in shelving come to life!

Start by putting your base shelf in- just right on top of that base. Make sure again that it is level and shim as you need to. Use brad nails to hold this in place- everything is being built on top of this.

This is the part that helps it come together so easily so if I’m not making sense to you in this paragraph- go watch the Instagram story highlight where I show it… once you’ve decided the exact height of your shelf- time to cut upright pieces out of the 1/2″ MDF. These upright pieces will be cut to the bottom edge of your shelf- the shelf will rest on top of them. These should have already been cut to your depth by Home Depot or wherever (mine were in 11″ strips, remember) so you are only having to think length of each board here.

When you’re doing your exact measurements for cutting, make sure to take into account the 3/4″ shelves that you will be putting in. If you’ve had to shim at all to get things level, this will affect your design measurements so it’s really important to to exact measurements before you cut and build.

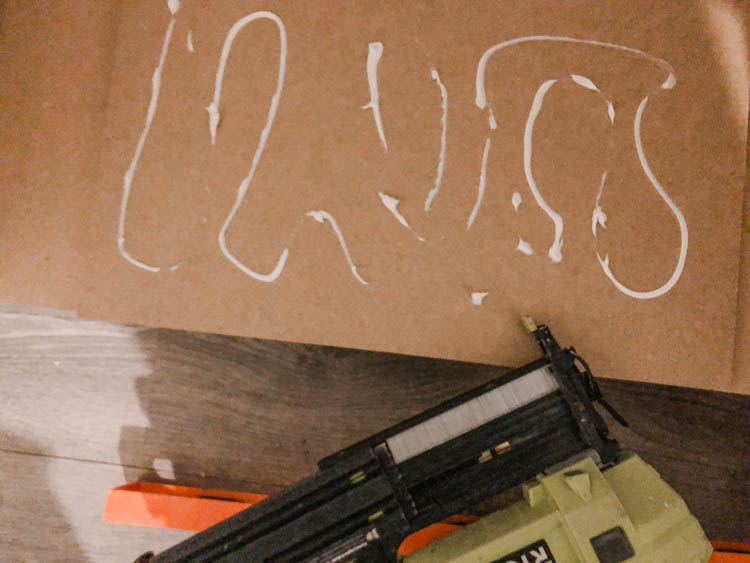

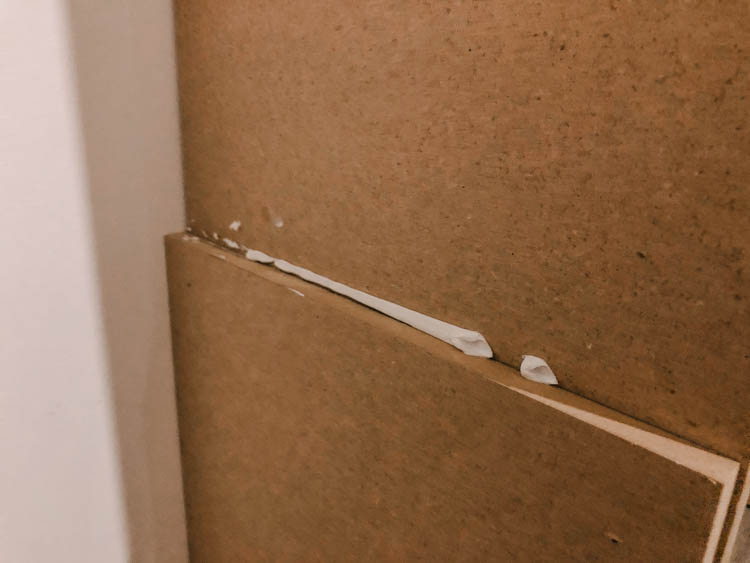

Attach these shelf support uprights using brad nails and adhesive. I used ‘No More Nails‘. I used 5/8″ brad nails on the centre shelves (so they didn’t pop out into the other side of my shelves) and longer ones into the walls. Then, cut and put first next shelf on top of those supports. Make sure it’s level and add some adhesive to the edges of the shelf and a couple nails to hold it in place (into the upright supports you just placed). I liked to work horizontally, then vertically. So I would do both the shelves on the bottom first and level them to each other, then keep working your way up!

When you get to those top couple shelves, I’d remeasure and split the difference if you’re out a little bit- these two top shelves will be the same size even if they’re different from the bottom. I purposely made my bottom shelves a little bigger to accommodate some big books, vases and magazine holders.

The top shelf of this diy built in shelving will also need a top- you don’t want to look at the 2×4 header! Just make another shelf the same way, and pop it on the uprights- you’ll only see the bottom of this one.

How to Accommodate a Doorway in diy Built in Shelving

IF you are building around a cased opening like I am (a doorway), you will want to secure that upright to the shelves. Use longer brad nails from the cased opening into the shelf. These patch easy with woodfill after and is worth the patching to make it all secure!

You will also need to decide if you want to case out over the door. I chose to case this out without making it into a shelf since I am planning on running a barn door rail here. You could put a shelf here if you rather, but that will affect your design plans.

How to Trim Out Built In Shelving

At this point… your diy built in shelving is complete! It just doesn’t look beautiful. Now we want to trim it out and get it looking custom. I started with the baseboard. I ran MDF to cover the 2×4 framing and level it with the uprights and base of the shelf. THEN I added a baseboard to wrap around the bottom of the shelves. Since the floor wasn’t level and I wanted the baseboard to be level to the bottom shelf, I added a quarter round moulding as a shoe along the baseboard- this hides any imperfections in the floor level.

For the header, I shimmed out any areas the 2×4 header didn’t meet the edge of the uprights and then I ran a pine board across the top of the entire built in. I did build a header for the gap above the doorway too. If you aren’t planning hanging anything off this header- just use MDF here, it has a much cleaner finish.

On the header above the cased opening, you’ll need to add a bottom to hide that 2×4 frame so use MDF for that.

Now we buff up the shelves and uprights! I used 1×2 moulding for this. When we built these last time, we cut our own from sheets of MDF to save money. Again- since I was doing this myself, I didn’t see myself manhandling a sheet of MDF through the table saw into 2″ strips by myself so I opted for ease and purchased the trim.

I ran the 1×2 on the uprights first, tacking it in place with brad nails. Make sure these cuts are perfectly to length. I lined them up as follows: on the outside walls, make them tight to the wall- they will hang over your shelves a bit and thats a-okay. On the middle uprights, they will JUST cover your 3 layers of MDF. Centre it on there. If you’re against a cased opening like this (or are not going wall to wall), line the edge of your trim up with the outside edge of your upright so from the outside, this looks flush. Again, the trim will hang over the shelves on the inside a bit and that’s the plan.

Then, cut your MDF trim for your shelf faces. Line them up so the shelf has a flush, flat surface- let the overhang be at the top of the shelf below.

Where to use Wood Fill vs Caulk on DIY Built in Shelving

Now it’s time to finish these babies up! Don’t make the mistake I did and celebrate being done yet. You’re totally not. This process is time consuming but really worth it. This is what gives your work a custom look.

Use wood fill to fill all nail holes and gaps that are flush. For example, between the shelf and the trim piece- you want that to all look like one, so you would use wood fill here. If it’s a nice flat surface for you to sand… wood fill. Make sure the wood fill you use is paintable and if you’re painting white- even get white wood fill. Make sure to fill any gaps a bit above the hole so you can sand it down flush.

Sand the wood fill and all surfaces of your built ins to ensure paint goes on evenly and everything is smooth. I use a palm sander for this and 180 grit sandpaper. If you have a really rough area, you can use 100 grit sandpaper, but I wouldn’t go below that for MDF.

Use caulk to fill any corners. Do this after you’re done sanding your wood fill. I have a video… that’s super awkward because it’s my first video EVER- but it shows how to caulk to fill baseboards and corners like you’ll need to do here. One thing I would correct from that video though is if you’re filling mitred corners like on the baseboard around the cased opening- use wood fill here, it’s much more durable. Always caulk before you paint- it will hold up so much better! Caulk collects dust and doesn’t wipe away as easy as dust on painted surfaces.

How to Paint MDF Open Shelving

I asked what you guys would want to know about these shelves in my IG stories and one of the questions was how to make them look not so… painted. MDF is a paint HOG you guys. I have been told to always always use an oil based primer on it first. It stinks, I know… and it’s impossible to clean- yep. I buy a disposable roller cage and tray for it because paint thinner with kids around scares me and I just go for it. It will seal your MDF so you don’t need to do 9 coats. I use this one. If you use a different one, just make sure it’s suitable to go over with latex paint after.

Then paint cabinet paint or door and trim paint. It took two coats to get this even coverage. I could probably do a third. I use a satin finish and I roll it on. Brush strokes almost always show on flat surfaces like this, so I brush the corners and hard to reach nooks then roll right overtop of it. A good cabinet paint is self levelling so it won’t have texture to it. I know a lot of US bloggers recommend using a paint additive for self levelling (Floetrol is the one I see often) but it’s not available in Canada that I know of.

If you’re really craving a smooth finish- a paint sprayer is the way to go. I have a post with beginner tips on a paint sprayer here and a post recently with more tips here. I chose not to do that in here because we were working on other projects simultaneously where we needed to go through that doorway so I didn’t want to mask it all off.

Phew! That’s a LOT of information, but you guys had so many questions over on IG about my diy built in shelving project and I wanted to make sure I answered them all! I hope that this post is informative and helpful for you. Let me know if you have any questions about making your own DIY built in shelving!

Frosted Whites Christmas Tree

Frosted Whites Christmas Tree

Thank you for this tutorial! This is exactly what I needed for a project that I want to do. Love your site:).

I’m so glad! Hope it went well :)

I used this as a guide to build a three section shelving unit in our laundry room. I left out all but one shelf in a wider (36″) section on the far right to have room for a rod to hang clothes (I am building it 16″ deep). I framed the base on the far left differently to have it open to the floor to be able to roll in a wheeled laundry sorter. I designed each shelf to hold a medium sized laundry basket. Thank you for this! Although I modified it a bit, without you I wouldn’t have known where to start. I looked at the primer you used but I dont think it will be safe for my situation as the laundry room is poorly ventilated and near the furnace and water heater. Do you have another you would recommend?

Floetrol is available in Canada and has been forever. I used to sell it at a paint store. Keep an eye out for it!

Ooh I’ll have to look for it!

Thank you so much for this tutorial! I am excited to DIY my own built-ins as i’ve been wanting one since FOREVER. I had a question about the uprights, is it structurally important / needed as i’m looking to put in builtins between two walls on either side of a fireplace. Also just wondering if you its important to have the base connected to the uprights.

Hoping you can help, thank you!

I would connect it all for the most stability but it’s hard to say!

This is really nice and informative, thank you.